Nice idea but can plants REALLY do

this?

What if you're short of

water?

Growing stuff takes water. Lots and lots of

water. So this may look unworkable in drier areas. It

isn't.

Because in conventional agriculture, most of the water you apply

(99.24% in the above Hedera helix example) is

wasted - it transpires straight to

atmosphere so it's gone, so you need to get more.

HCC is a closed environment, meaning the transpired water

is condensed back out and re-used.

But where do we get the water from in the first place? From

basic chemistry. We know burning carbon fuel releases lots of CO2 -

but it also releases lots of water.

Here's the equation for wood burning, but other fuels are

broadly similar:

C6H12O6

|

+

|

6 O2

|

=

|

6 CO2

|

+

|

6 H2O

|

So when HCCAS recovers the heat from the flue

gas we'll ALSO condense out LOTS of water.

There's another reason to reduce water vapour

emission.

Recent science identifies rising

water vapour as magnifying global warming - scavenging water

this way dramatically cuts water vapour emission to

atmosphere.

SO now we're reducing CO2, making

food, biomass, or

biochar, making O2, providing

resilient agriculture AND reducing water

vapour's global warming impact. And can do so profitably,

producing funds for the local economy or more environmental

projects.

That's pretty cool for a few plants.

Won't HCCAS cost as much as CCS - or more

- to implement...?

Highly doubtful. Think about it: CCS needs

complex pressurized long-distance transport infrastructure;

HCCAS doesn't.

CCS demands large-scale secure "burial" sites which subsequently

need to be guarded and monitored,

forever; HCCAS

doesn't.

CCS consumes a lot of energy doing what it does, so you actually

need to produce lots MORE energy just to CCS the CO2 that you've

made from, er, producing the energy to operate the CCS... go

figure. HCCAS doesn't.

CCS presents a high-value attractive terrorist target with a

very long and largely unprotectable perimeter (including 1000s of

miles of pipeline); HCCAS doesn't.

BEST OF ALL HCCAS can reach all the places in

the world CCS can't (economically) get to, it's infinitely

flexible, it feeds people,

improves our air, encourages

re-forestation (and biodiversity)

and it's greener than a very green thing so -

unlike CCS - will be welcomed by local populations

rather than resisted. That should also help re-invigorate

rather-jaded levels of public enthusiasm for green

projects.

And because HCCAS is all the same, once the first is built

subsequent builds are easy. Extending that logically to

mass-produced modules means we can do lots and LOTS of

installations very, very fast and very cost-effectively. According

to the cost analysis done for the

HCCAS 2016 MIT SOLVE entry HCCAS can even be

cash-positive.

And that's something CCS will never be.

Here's another interesting thing about CCS.

Trying to find a way - any way - to improve its dire economics, a

use has been found for the CO2 the CCS has buried. Any guesses

what? You'll love this... it's used for EOR.

"EOR"? Yep - Enhanced Oil Recovery. The CO2 is

pushed down dying oil wells to squeeze out more oil. The best use CCS has for its captured CO2

is extracting MORE fossil fuels to make MORE CO2. Yep,

seriously. D'uh.

Ask yourself:

- Would you rather spend

money ONCE on something that keeps

on

GIVING BACK, like

HCC?

- Or would you rather

KEEP ON spending lots of money on

something that will keep on

TAKING - forever - like CCS?

Use brownfield = save

greenfield

HCC doesn't need fertile soil, a sunny aspect, the right

rainfall, or much else.

It doesn't need to be in an attractive area with shops and

schools, or handy for the motorway.

So it's ideal for brownfield site that's

unworkable for conventional agriculture and unsuitable for people,

meaning it frees-up greenfield land for people,

reforestation, or nature. Don't know how that pans-out financially,

but I'm pretty confident how it pans out rationally.

Hang on - aren't we

talking 1000s of tonnes of plants a day?

Yep. The planned

Drax 100% biomass-fuelled 300MW power station was expected to

burn 1.4 million tonnes

of

biomass annually (that's just under 4000 tonnes a

day). So, for an emitter that size, yes.

BUT think that through - we're ALREADY planning to handle that

much biomass, shipping it in. So there's nothing inherently scary

about handling big numbers of biomass. Now imagine if we could MAKE

the biomass locally instead of shipping it in,

converting emitted CO2 back into more biomass right there on site.

We won’t achieve 100% capture, but if we assume just

30% then as well as releasing 1000's of tonnes of

oxygen, in one year HCC on this installation would

save:

- all the cost and emissions created by shipping

30% of 1.4 M tonnes - that's 420,000 tonnes - of biomass (most

UK consumption is sourced from overseas)

- the global warming impact of the 30% of CO2

recovered; if we assume biomass to be around 40% carbon, we have of

the order of 40% of the recovered

30% of 1.4M = 168,000 tonnes of

carbon (that's roughly 620,000 tonnes of

CO2).

- The agricultural land you'd need to GROW

420,000 tonnes of biomass. So it could be used for reforestation,

or for people, or...

If your emitter can't use biomass - say you

have a gas-fired plant or a coal- or oil-fired cement works - HCC

can produce food instead, or can produce a

fast-growing crop for biochar to sequester carbon

directly.

Quickly, cheaply, flexibly. Did I mention it

makes O2 as well? And the food HCC makes - really efficiently -

means you free-up 1000s of acres of conventional agriculture, so

you can re-forest that land and those trees will near-permanently

sequester carbon (as well as aiding biodiversity, greatly improving

our environment, and providing a source of green building

materiel).

Biomass, biochar, or food, if I'm right about HCC we can spend a

few billion implementing it to achieve

permanent

carbon reduction AND

all these other benefits.

Or, we can spend many trillions

re-locating

populations, draining floods and starving from drought while

we watch the Earth turn into Venus.

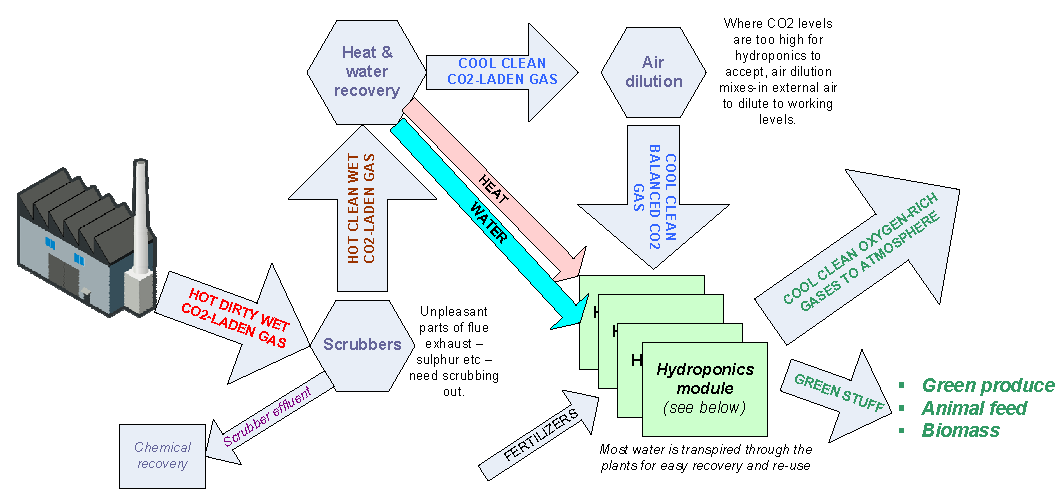

Here's an overview of

HCCAS: